|

|

|

|

|

|

|

|

| The LMS series high-precision tension detector is a very precise combination part, with the TC series tension controller, the control speed and tension show outstanding control and stability performance. |

|

|

|

• |

Utilizing high-tension steel plate and a special heat-process technique to achieve the rigidity of impact resistance and high stability. |

• |

The detection loop uses a high-frequency linear differential circuit coil, which has good anti-interference ability. |

• |

LMS series tension detector has various specifications and is easy to install. |

|

|

|

|

| Tension Detector LMS005 ~ LMS050 Specification |

|

| Model No. |

LMS-005 |

LMS-015 |

LMS-030 |

LMS-050 |

| Applicable load |

5kg |

15kg |

30kg |

50kg |

|

|

| Load direction |

Compression and Stretching |

|

|

| Mounting method |

Wall-mount, Plane-mount, Ceiling-mount |

|

|

| connect |

7.5M x 4C Isolated-cable

(The M4 screw at the outlet end of the body is the grounding terminal,

it should be grounded. The grounding resistance must be lower than 100Ω) |

| Ambient temperature |

-5°C~45°C (Non-explosion-proof) vibration 2m/s2 or less |

| Weight |

1.8kg |

| Applicable controller |

TC-2010、TC-2050、TC-2050P、TC-2060、TC-3050、TC-3210、YTTC-260A、YTTC-5260 |

|

|

|

|

|

| Tension Detector LMS100 ~ LMS400 Specification |

|

| Model No. |

LMS-100 |

LMS-200 |

LMS-300 |

LMS-400E |

| Applicable load |

100kg |

200kg |

300kg |

400kg |

|

|

| Load direction |

Compression |

|

|

| Mounting method |

Inclined surface, Flat installation |

|

|

| connect |

7.5M x 4C Isolated-cable

(The M4 screw at the outlet end of the body is the grounding terminal,

it should be grounded. The grounding resistance must be lower than 100Ω) |

| Ambient temperature |

-5°C~45°C (Non-explosion-proof) vibration 2m/s2 or less |

| Weight |

3kg |

| Applicable controller |

TC-2010、TC-2050、TC-2050P、TC-2060、TC-3050、TC-3210、YTTC-260A、YTTC-5260 |

|

|

|

|

|

| Tension Detector LMS600 ~ LMS1000 Specification |

|

| Model No. |

LMS-600 |

LMS-1000 |

|

|

| Applicable load |

600kg |

1000kg |

|

|

|

|

| Load direction |

Compression |

|

|

| Mounting method |

Flat installation |

|

|

| connect |

7.5M x 4C Isolated-cable

(The M4 screw at the outlet end of the body is the grounding terminal,

it should be grounded. The grounding resistance must be lower than 100Ω) |

| Ambient temperature |

-5°C~45°C (Non-explosion-proof) vibration 2m/s2 or less |

| Weight |

25kg |

| Applicable controller |

TC-2010、TC-2050、TC-2050P、TC-2060、TC-3050、TC-3210、YTTC-260A、YTTC-5260 |

|

|

|

|

|

|

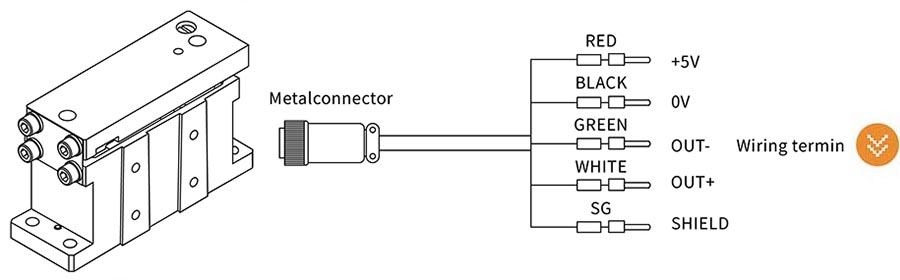

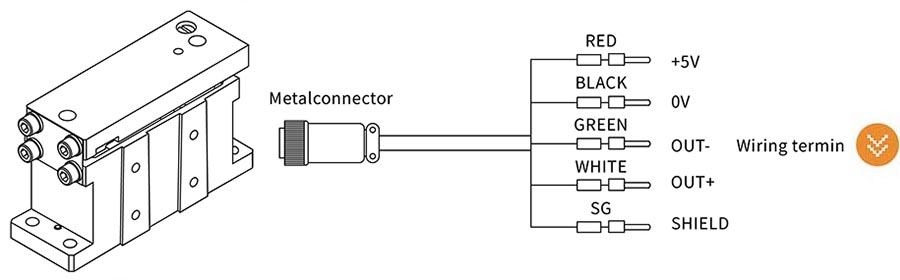

| Tension Detector LMS series Wiring diagram |

|

|

|

|

|

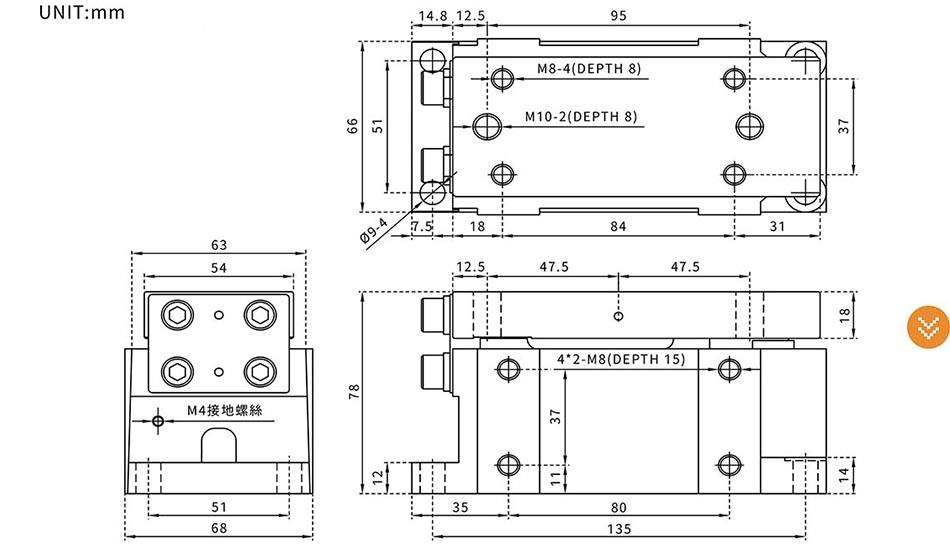

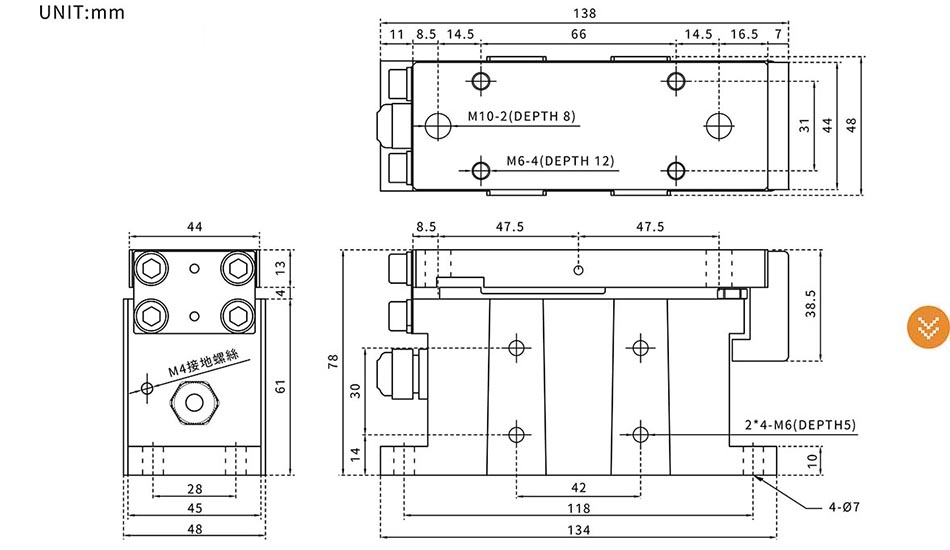

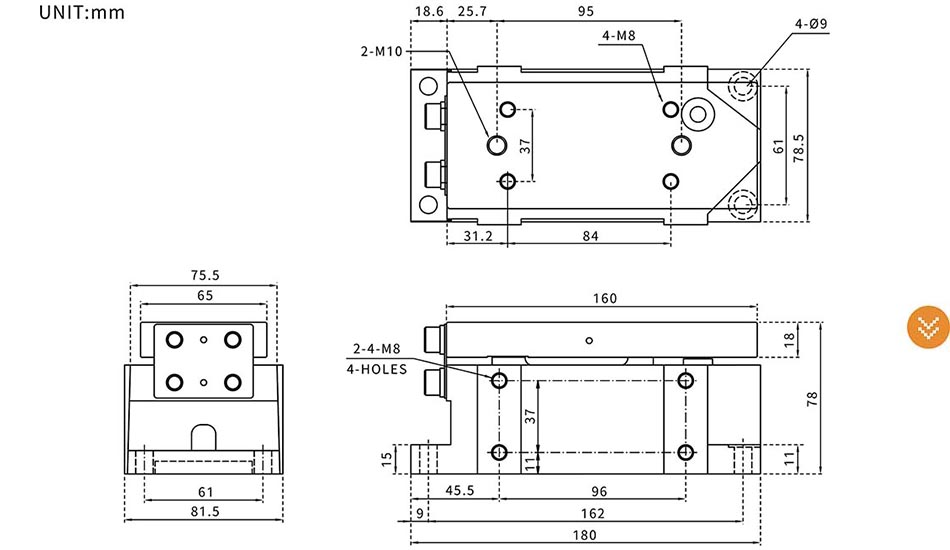

| 1. LMS 005~050 Dimension diagram |

|

|

|

|

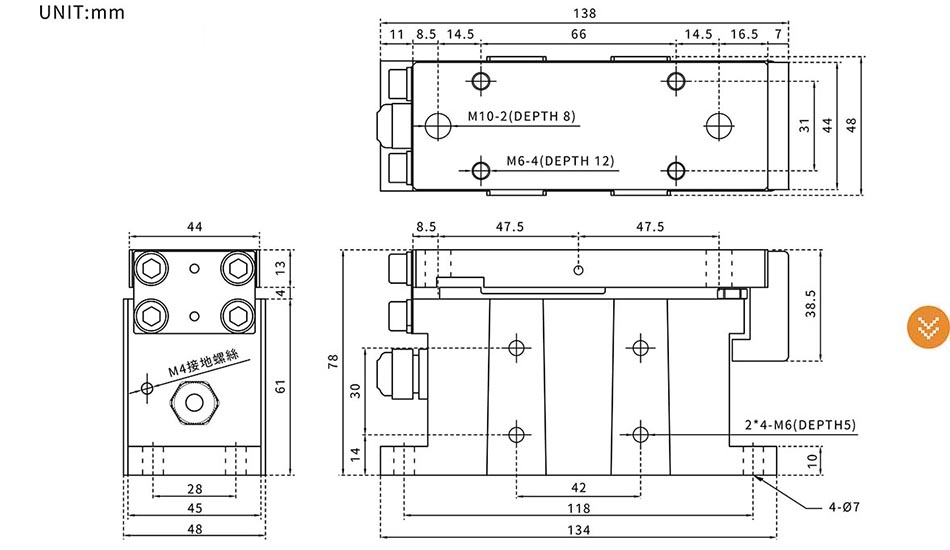

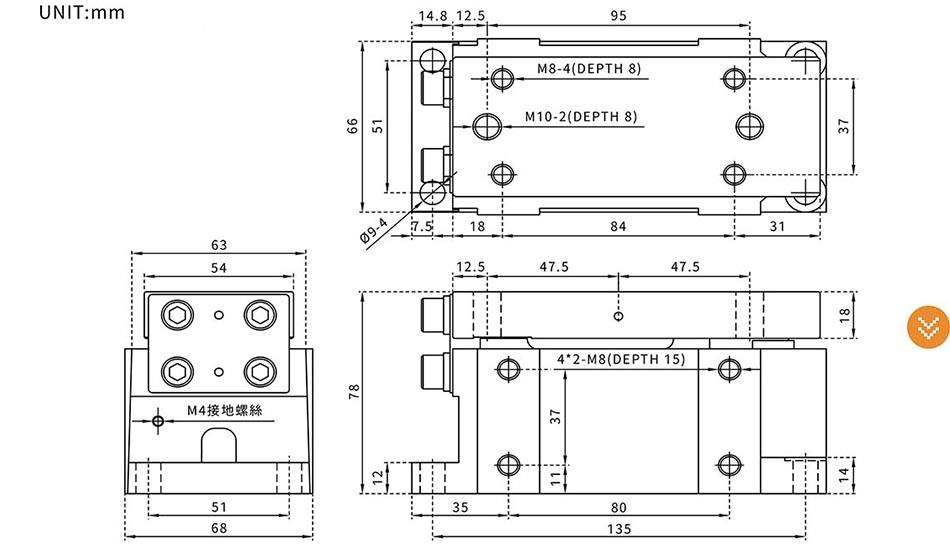

| 2. LMS 100~300 Dimension diagram |

|

|

|

|

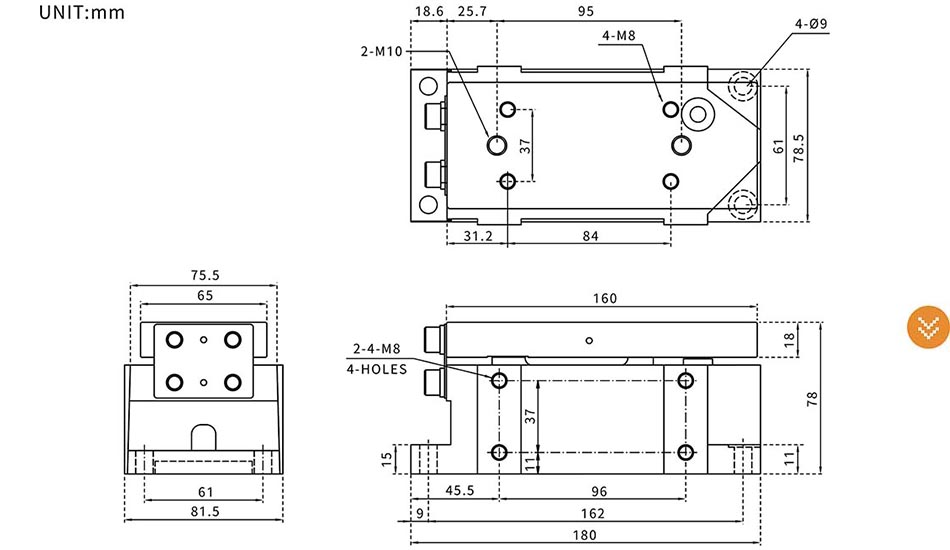

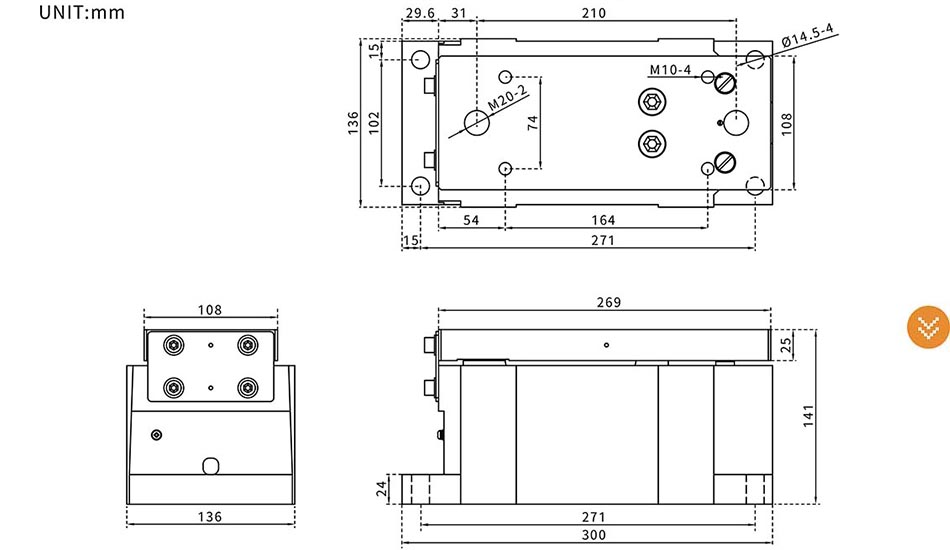

| 3. LMS 400~600 Dimension diagram |

|

|

|

|

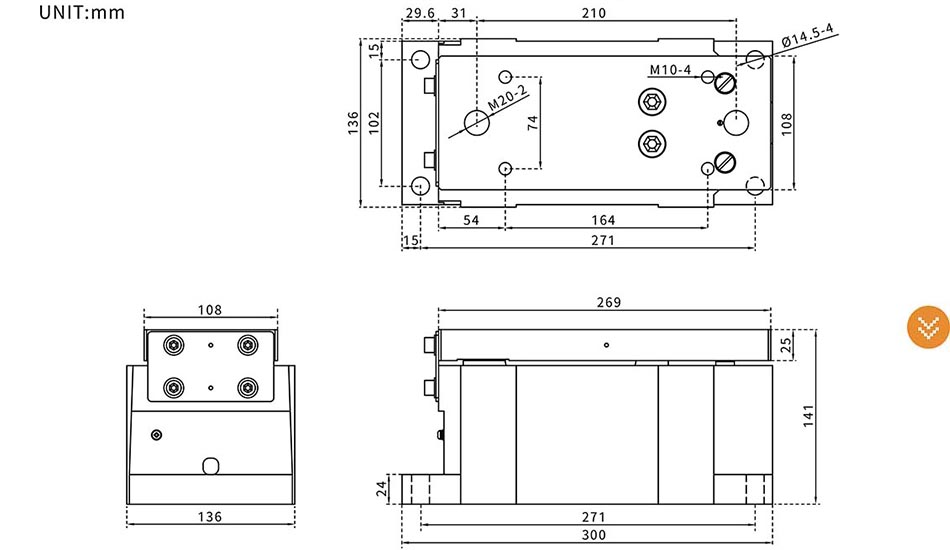

| 4. LMS 1000 Dimension diagram |

|

|

|

|

|

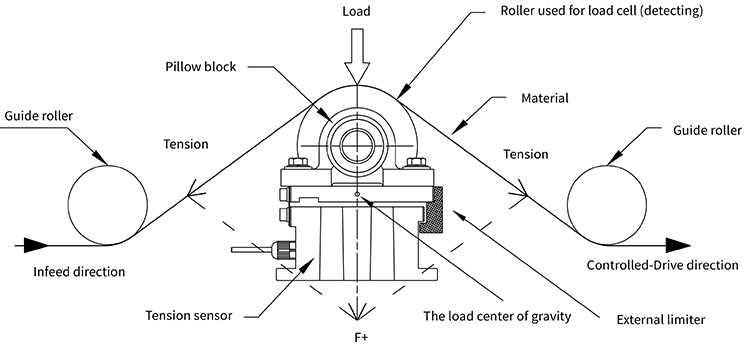

| Tension Detector LMS series Principle & Application diagram |

|

Principle description:

The LMS series tension detector is illustrated in the following figure.

After the processing material passes through the roller, it generates a downward pressure force, which causes a slight displacement change up and down on the detector. A high-tensile steel plate is installed inside to generate a rebound force.

After the differential transformer senses the displacement, it outputs a changing voltage signal to the controller for achieving the purpose of measurement.

This structure is equipped with a high-frequency signal amplification loop, which has good stable performance for antiinterference and temperature changes.

When the material width is wide, even material is one-side expansion, the tension detector can also correctly detect material tension and there is one tension detector at each end of the roller, so a total of 2 units are used.

▪If it is not a full-width material, tension detection can be performed with only one tension detector on one side.

▪In the case of electric wires, steel cables, etc., a tension detector installed can detect tension, performed by a roller.

As shown in the figure below, the load on the tension detector is the sum of the tension vectors (F+), plus the weight of the tension detection roller.

|

|

|

|

|

|

|

|

| Tension Detector LMS series Application example |

|

|

|

|

|

| Tension Detector LMS series is applied to detect the tension of fabric in rewinding unit of fabric laminating machine. |

|

|

|

|

|

|

|

|