Principle description:

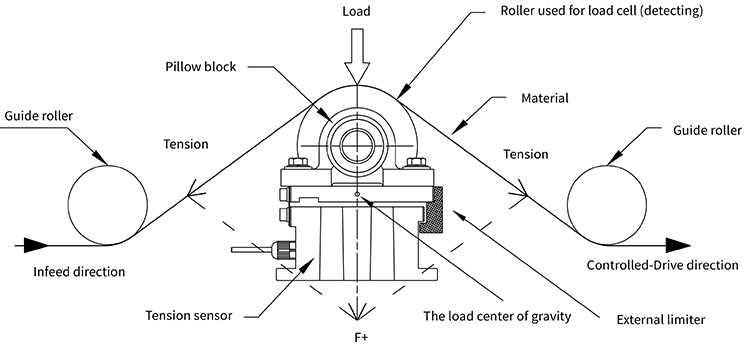

The LMS series tension detector is illustrated in the following figure.

After the processing material passes through the roller, it generates a downward pressure force, which causes a slight displacement change up and down on the detector. A high-tensile steel plate is installed inside to generate a rebound force.

After the differential transformer senses the displacement, it outputs a changing voltage signal to the controller for achieving the purpose of measurement.

This structure is equipped with a high-frequency signal amplification loop, which has good stable performance for antiinterference and temperature changes.

When the material width is wide, even material is one-side expansion, the tension detector can also correctly detect material tension and there is one tension detector at each end of the roller, so a total of 2 units are used.

▪If it is not a full-width material, tension detection can be performed with only one tension detector on one side.

▪In the case of electric wires, steel cables, etc., a tension detector installed can detect tension, performed by a roller.

As shown in the figure below, the load on the tension detector is the sum of the tension vectors (F+), plus the weight of the tension detection roller.

|

|