![]() |

|

|

|

|

|

|

|

|

TC-2050 & TC-2050P tension controllers use the feedback signal of high-precision LMS series of tension detectors to stabilize tension control. It uses two chips of 16 bits of the microprocessor

to do computing division, having the performance of fast and stable tension control, and is suitable for tension control for unwinding/infeed, center proportional linkage, and rewinding / receiving

.

|

|

|

• |

The functions of unwinding / infeed, center proportional linkage, and rewinding / receiving can be set by the internal DIP switch of TC-2050/P. |

• |

It includes the digital type of line-speed proportional linkage function, which can make line speed in accelerating or decelerating until the stop keeps stable tension control. |

• |

Multi-level P.I.D, which can present a fast and stable function when speed is variable at any time. |

• |

Large subtitles high brightness LED numeric display, which can be selected by the parameter “SRC” to display different units, such as kg.m/min, etc. |

| • |

The parameter function is symbolized by English abbreviations and can be easily operated without relying on the manual. |

| • |

There are LED window displays, “RUN” is for running, “CENTER” is for center proportional linkage, “WINDER” is for unwinding/rewinding, “SENSOR” is for the abnormal detector, “ERROR” is for the abnormal message. |

| • |

The terminal can receive a pulse signal, which is the signal source for calculating the diameter of the reel. |

| • |

Line-speed signal can accept an analog signal of DC 0 ~ 10V. |

| • |

There are two sets of terminals, which are digital multi-functions contact, that could be for the acceleration or deceleration compensation. |

| • |

The terminal can provide an output signal of DC 0 ~ 10V for actual tension display. |

| • |

It includes RS-485 communication function, and could connect to PLC, human machine interface, and industrial computer for control. |

| • |

The terminal’s output signal of DC 0 ~ 10V could directly control the torque controller, a current-control type of vector inverter, DC motor drive, and servo motor drive. |

| • |

Working with LMS series of load cell, rated load of 5Kg ~ 1,000Kg (50NM~10,000NM). |

|

|

|

|

|

|

|

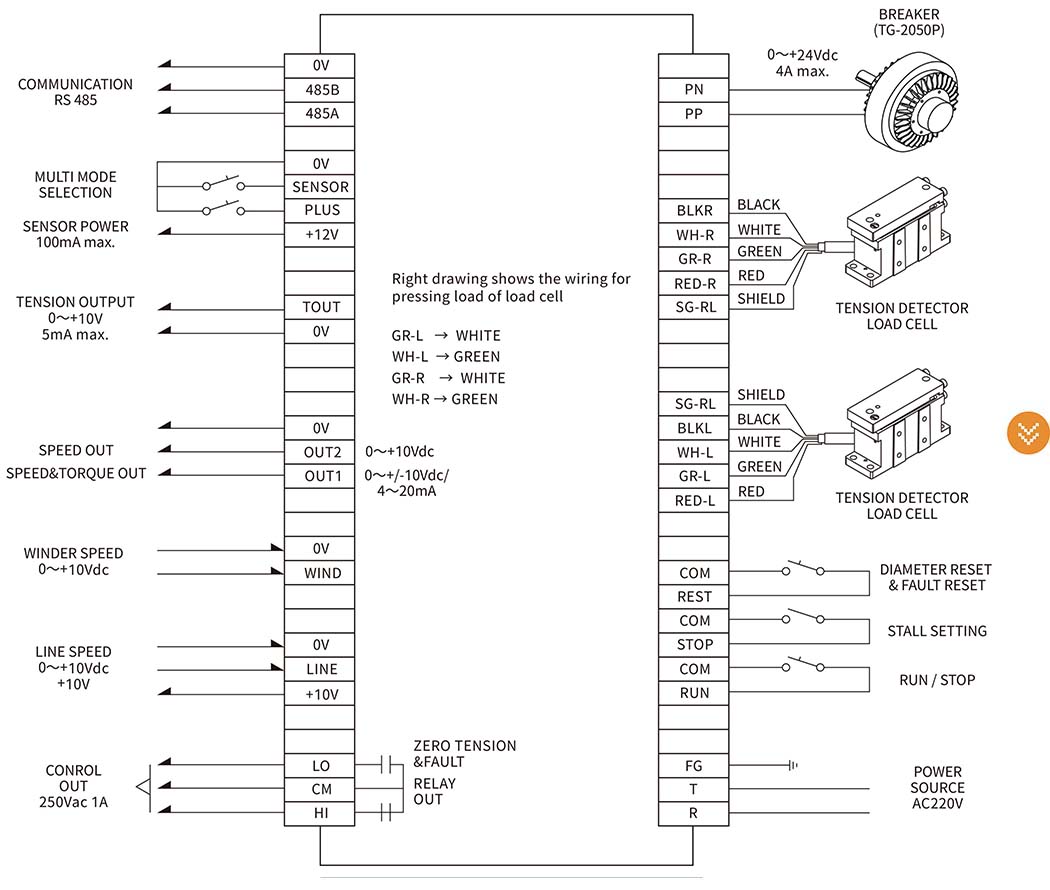

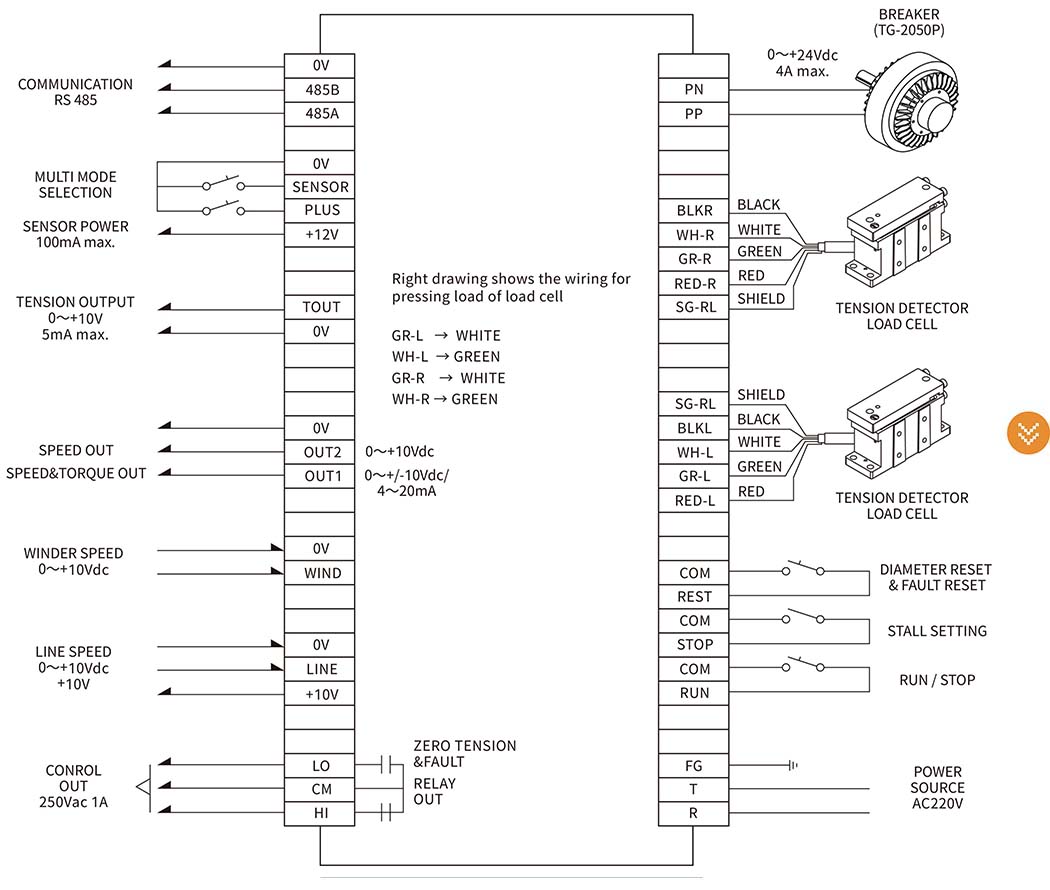

| Tension controller TC-2050,TC-2050P Wiring diagram |

|

|

|

|

| Tension controller TC-2050 Dimension diagram |

|

|

| Tension controller TC-2050P Dimension diagram |

|

|

|

|

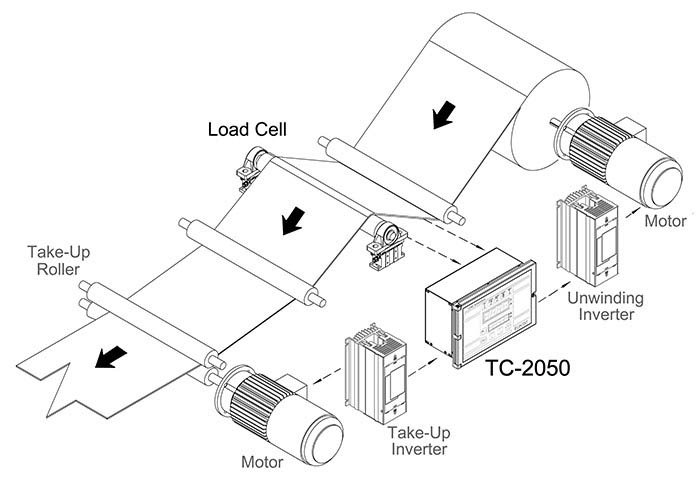

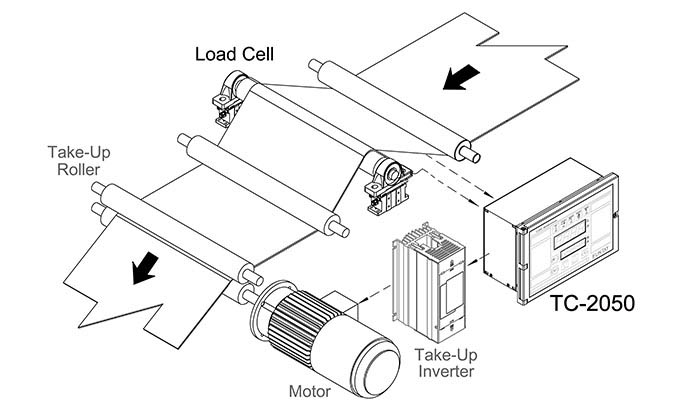

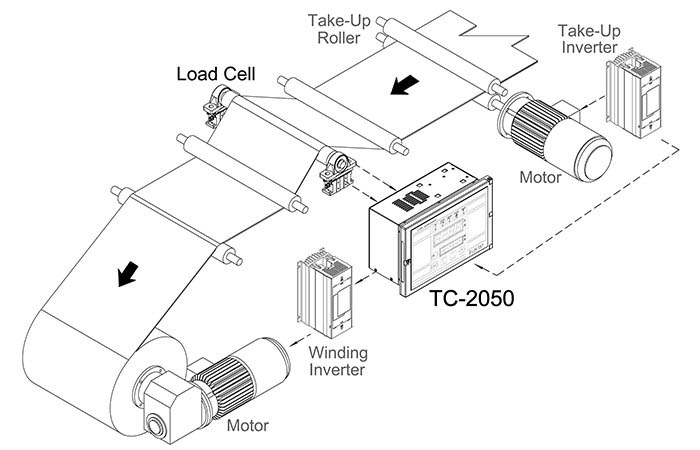

| Tension controller TC-2050,TC-2050P Application diagram |

|

| Unwinding tension control |

|

|

| Central guiding tension control |

|

|

| Rewinding tension control |

|

|

|

|

| Application example |

|

|

|

|

|

| The application example of picture is showed that Tension Controller TC-2050 is applied to the tension control in unwinding, rewinding process of Fabric Laminating Machine, to keep fabric surface be flat in laminating. |

|

|

|

|

|

|

|

|

|

|

![]() |

| |

|

| Euntay Electric Co., Ltd. |

Motion Control System Manufacturer in Taiwan, |

| Tension Control System Manufacturer in Taiwan, |

| Edge Position Control System Manufacturer in Taiwan, |

| Tension Controller, Load Cell , Tension Detector, Sensor |

| Edge Position Controller, EPC, Edge Guide Sensor,Web Guiding, |

Ultrasonic EPC Detector , Infrared EPC Detector , Electric Cylinder , |

| Hydraulic type Drive, Double loop Hydraulic Drive, Web Guide |

| Web Guiding Machine, DC Motor Drive, Digital DC Motor Drive |

|

|

|

|