|

|

|

|

|

|

|

|

| TC-3050 according to “TC-2050 General-Purpose Tension Controller”,reduces volume and becomes an embedded type of industrial design, it is suitable for mounting in the control box, TC-3050 is specially designed for tension control for high-speed rewinding/unwinding, and it has procedure control function for material roller switch.

. |

|

|

• |

Accepting pulse signal, which is the signal source for calculating the diameter of the reel. |

• |

Accepting tension detection signal (LMS series, PDSA series of tension detectors) as the tension signal source for computing material tension in the production process. |

• |

It includes the digital type of line-speed proportional linkage function, which can make material stable tension in the process of production. |

• |

Multi-level P.I.D computing capability can fast stabilize material tension variations in the process of production. |

| • |

Offering digital multi-functions contact, which could be for acceleration or deceleration compensation. |

| • |

Offering various drive unit control functions:magnetic powder brake / clutch, torque controller / vector inverter/dc motor drive/ servo motor drive. |

| • |

It includes RS-485 communication function, and could connect to PLC, human machine interface, and industrial computer for control. |

| • |

High brightness LED numeric display, which can monitor remotely, switch-key can display input signal, output signal, slip amount, kg.N.%.... |

| • |

It can simultaneously output two sets of control signals for the drive speed and current command. |

| • |

Two sets of terminals accepted external digital input signals that can be set for positive logic or negative logic control, Auto./Manual function switch, diameter taping tension curves function, etc. |

| • |

Having remote/external functions for tension setting (0 ~ 10V). |

| • |

Working with LMS series of load cell, rated load of 5Kg ~ 1,000Kg (50NM~10,000NM). |

|

|

|

|

| Tension controller TC-3050 Specification |

|

| Applicable load cell |

5~2,000Kg |

| Supply voltage |

Single phase,AC 220V, 50/60Hz |

| Surge current |

2A |

| Power consumption |

40VA |

| Rated output |

DC 0 ~±10V (5mA max .) |

| Ambient temperature |

0℃~40℃ |

| Ambient humidity |

80%RH |

| Weight |

~3.0kg |

| Mounting |

Panel-inside, wall |

|

|

| Contact output |

High/Low tension alarm

Abnormal alarm |

One set of output A C220V / 1.0A

One set of output A C220V / 1.0A |

|

|

| Detector’s Input |

DC0~300mV (LMS/PDS(A)series of tension detectors) |

|

|

| External signal input |

| Input for diameter detection pule calculation |

| Line-speed signal |

| Tension setting |

| Rewinding-speed/Diameter signal |

|

|

|

| Contact input |

| Accelerated compensation |

| Decelerated compensation |

| Retentivity input |

| Tension setting (Manual/Auto) |

| Abnormal reset |

| Diameter reset |

| Start for Running |

|

|

|

| Control output |

| Speed output signal : DC 0~10V (5mA max .) |

| Torque signal :DC0~10V(5mA max .)/4~20mA |

| Tension-value signal :DC 0~10V(5mA max .) |

|

|

|

| Communication |

RS485 MODBUS RTU |

|

|

|

|

|

|

|

|

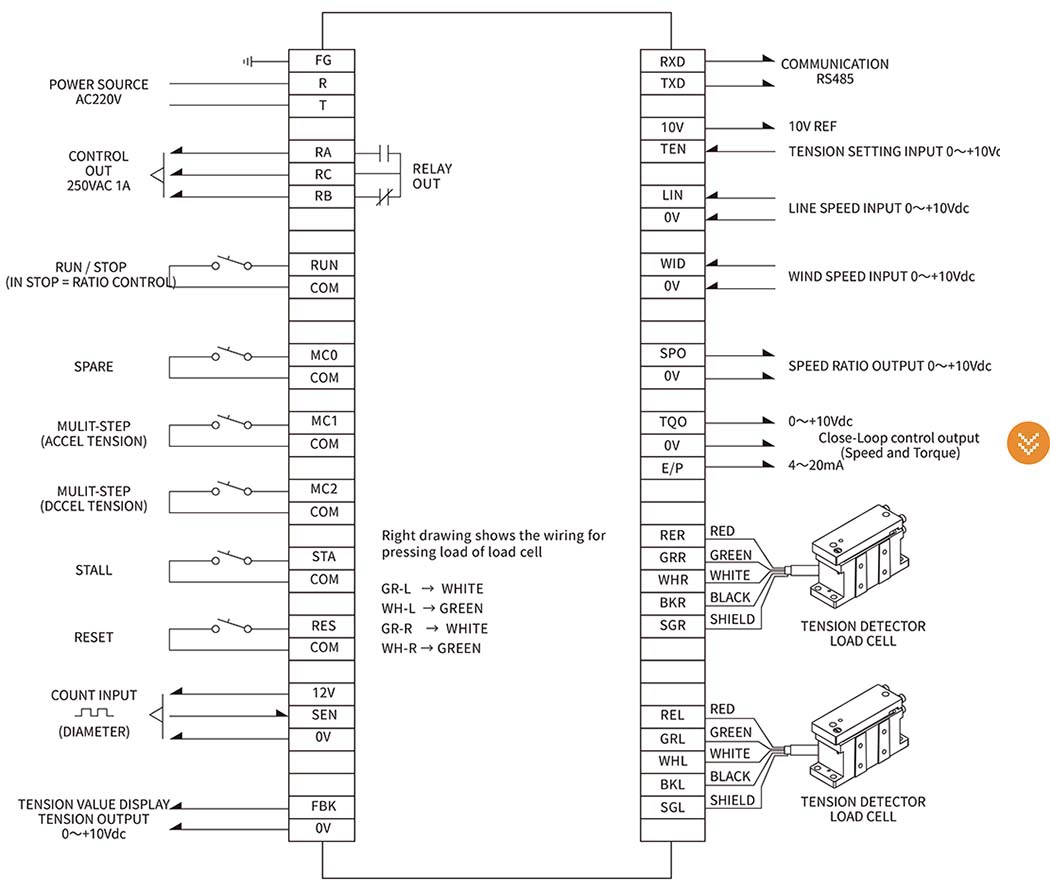

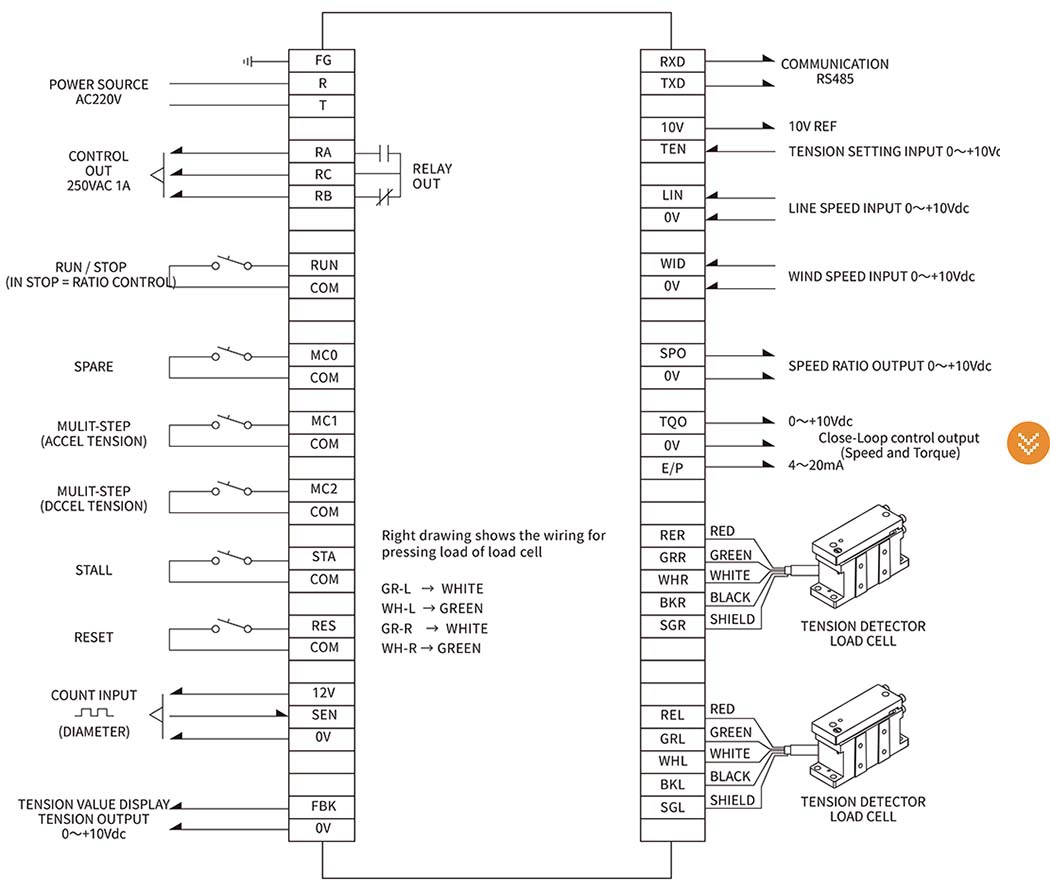

| Tension controller TC-3050 Wiring diagram |

|

|

|

|

| Tension controller TC-3050 Dimension diagram |

|

|

|

|

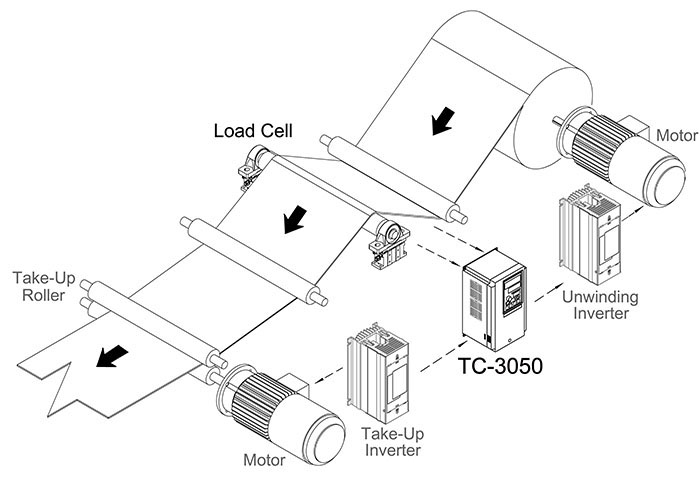

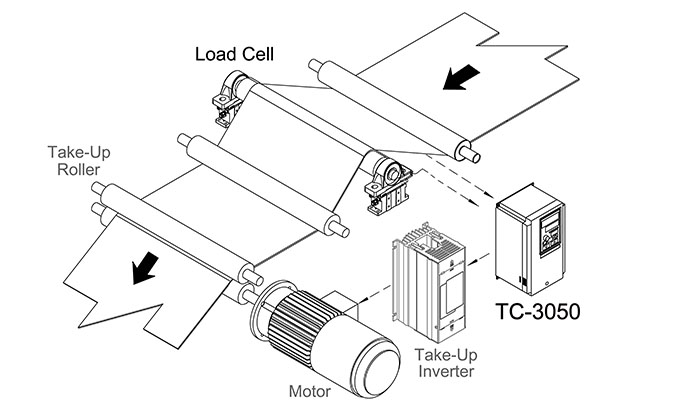

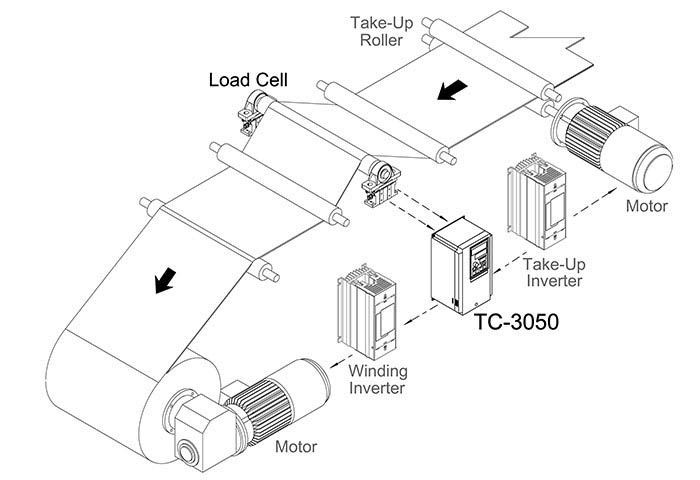

| Tension controller TC-3050 Application diagram |

| |

| Unwinding tension control |

|

|

|

|

|

| Central guiding tension control |

|

|

|

|

|

| Rewinding tension control |

|

|

|

|

|

|

| Application example |

|

|

|

| The application example of the picture is showed that Tension Controller TC-3050 is applied to the tension control of thin-film manufacturing equipments. |

|

|

|

|

|

|

|

|

|